ICOY GUARDIAN™

AI CERTIFIED AT THE SERVICE OF HUMANS FOR THE PROTECTION AND CONTROL OF DANGER AREAS

All ICOY® solutions, both MOVER™ and GUARDIAN™, offer advanced systems to support safety and accident prevention at work.

ICOY GUARDIAN™ supervises and controls certain internal and external areas (Red Zones) where hazards and risks associated with critical areas and interference between man and machine may occur. The aim is always to protect the life and health of workers and improve the efficiency of industrial operations.

In November 2024, ICOY GUARDIAN™ systems were awarded CERTIFICATION with CE Examination with the highest PLe score, according to the Machinery Directive 2006/42/EC – Annex IX, demonstrating that they are verified solutions that comply with the essential health and safety requirements defined in the Directive.

ICOY GUARDIAN™

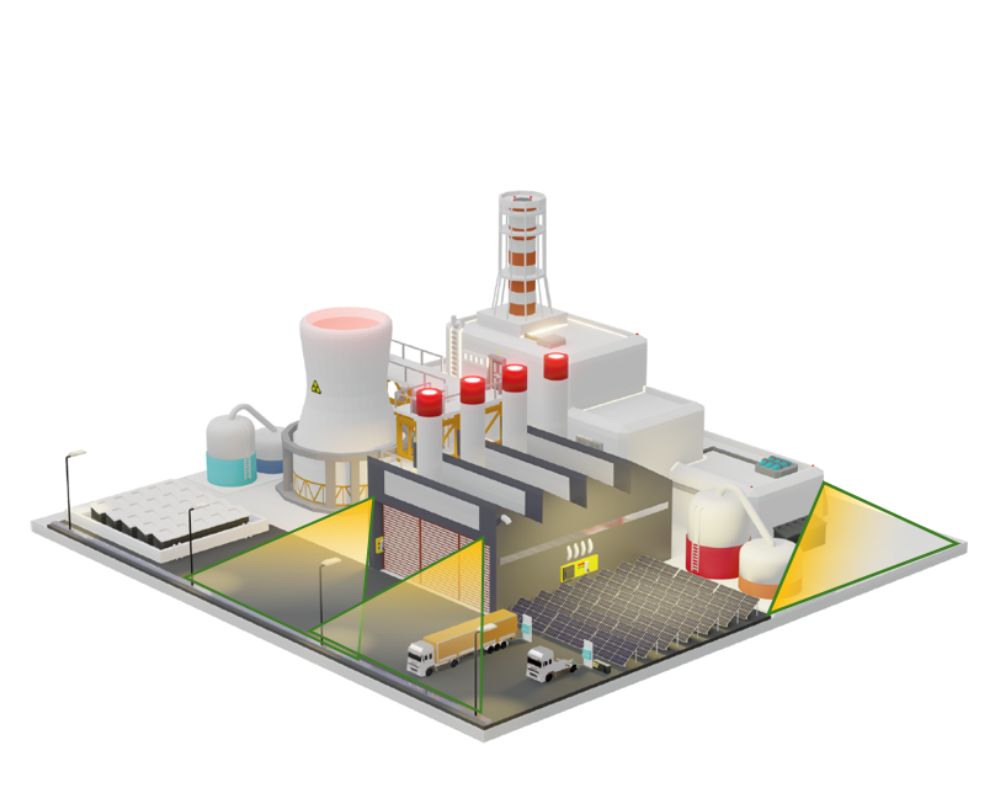

Our system covers indoor and outdoor installations and uses components with appropriate certifications.

A typical configuration of ICOY Guardian involves:

- Cameras for monitoring the critical area with the ability to view the area at 360°.

- The security perimeter can be visible on the ground, for indoor areas, through projection lamps specifically for industrial environments.

- Installation of audible and visual environmental alarms equipped with continuous siren and warning lights (traffic light).

- Information storage about perimeter violations (date, time and photo), Wi-Fi/ 4G-LTE connection with customer's information systems for monitoring events and using them for statistical purposes.

Artificial Intelligence, the heart of the system, is based on Deep Learning (*), which are algorithms created on convolutional neural networks that allow AI to automatically define a set of features that can be used to classify the content of an image. In this way, the analysis can be constantly improved as the number of images analyzed increases. The more experience gained by artificial intelligence the greater its ability to take care of us.

ICOY GUARDIAN™ has overcome the objective limitations of the technologies used until now, in personnel protection. It represents an evolution into the use of artificial intelligence to make workplaces safer, focusing on recognizing individual entities and monitoring them in critical areas, such as areas of human-machine interference in certain logistics and industrial operations.

(*) Deep Learning is an area of machine learning that is based on multi-level machine learning from input data. Each deeper level takes input the output data from the previous level extracting more and more information as the depth increases.

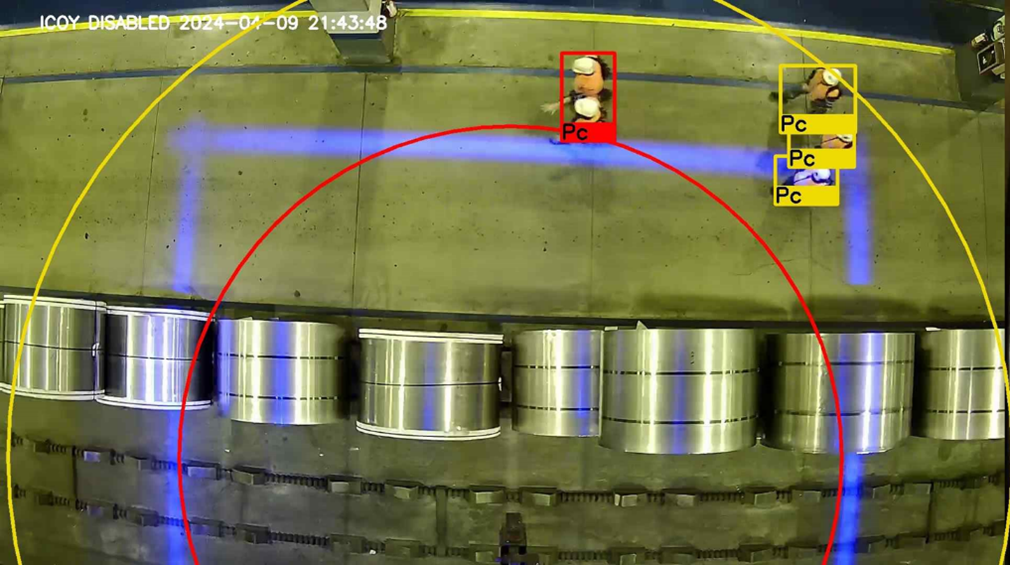

ICOY GUARDIAN™ can be installed on plant facilities to MONITOR CRITICAL AREAS by creating surveillance perimeters. An example would be monitoring areas near corrosive substances or areas where mechanical arms or robots operate. The perimeter is defined in accordance with environmental analysis and individual customer needs. The next level requires training the AI to achieve efficiency levels specific of the solution to make that perimeter “active” using audible and visual alerts. “Active” means the AI’s ability to identify the presence of a person (or other entity requested by the customer) inside the critical perimeter.

The processing takes advantage of the streaming video of the cameras, which possess a frame rate of 30 FPS, to search the required entities. When the AI detects one of these entities, it considers the location of it in relation to the critical perimeter and handles alerts to signal the dangerous situation.

Another application of ICOY GUARDIAN™ is the management of blind spots; for example, it will be possible to warn forklifts and/or workers in the near corners to avoid their interference or collision.

The companies we work with are now aware that ICOY GUARDIAN™ is not just a simple detection system, it is an evolved tool that allows them to diversify the recognized entities and be able to manage the needs of each customer!

We stand by each company’s side to help them build safer environments by examining their needs and critical issues, realizing goals!

ICOY Guardian's strengths

- Controls internal or external areas of the company by monitoring virtual perimeters.

- Management and control of blind spots through cameras positioned above the area to be surveyed to avoid human-machine interference.

- Management of up to 8 cameras per single central unit, this means monitoring up to 8 areas independent of each other. Diversify the activation of an event based on the recognized entity, for example, inside a red zone that is off limits to people but not vehicles.

- Production processes do not generate false positives, for example, presence of chips or scrap.

- Implements redundant security in areas where physical barriers of protection are present.

- It can replace physical barriers by giving machines and people the freedom to move.

- It controls a Red Zone from the top giving the possibility to some operators, for example, workers to invade the area with working tools needed to clean the machine without triggering the lockout. The emergency is activated if the system detects a human element, such as a hand.

- It counts the staff inside the area. This helps companies to limit the presence of workers in certain areas.

- Detects personal protective equipment worn by staff.

- It also detects just body parts.

WE ARE ON YOUR SIDE TO MAKE WORKPLACES SAFER THROUGH PATENTED, CERTIFIED AND AWARDED TECHNOLOGIES.

ICOY GUARDIAN™

BUILDING A SAFER FUTURE TOGETHER.